Abstract: The bourdon tube pressure gauge is a device that uses a bourdon tube for pressure detection. The accuracy of the pressure detection by the bourdon tube is very important in the inspection of mechanical equipment. In order to ensure the safe use of the pressure gauge and improve the accuracy and reliability of the pressure gauge measurement, this article analyzes and discusses some common problems in the measurement of the bourdon tube type general pressure gauge and the main points in the measurement process.

Overview of bourdon tube pressure gauges

According to the type of working principle, pressure gauges generally include liquid type, elastic type, piston type, electric measuring pressure gauge, etc. Among them, the elastic element pressure gauge is widely used in various fields of the national economy due to its wide measurement range, intuitive reading and economical characteristics. The functional principle of the elastic element pressure gauge is to use the elastic sensitive element to produce elastic deformation under the action of pressure. The magnitude of the deformation has a certain linear relationship with the applied pressure, and is displayed by the indicator of the measuring device or other display device through the transmission. The pressure measured by the institution.

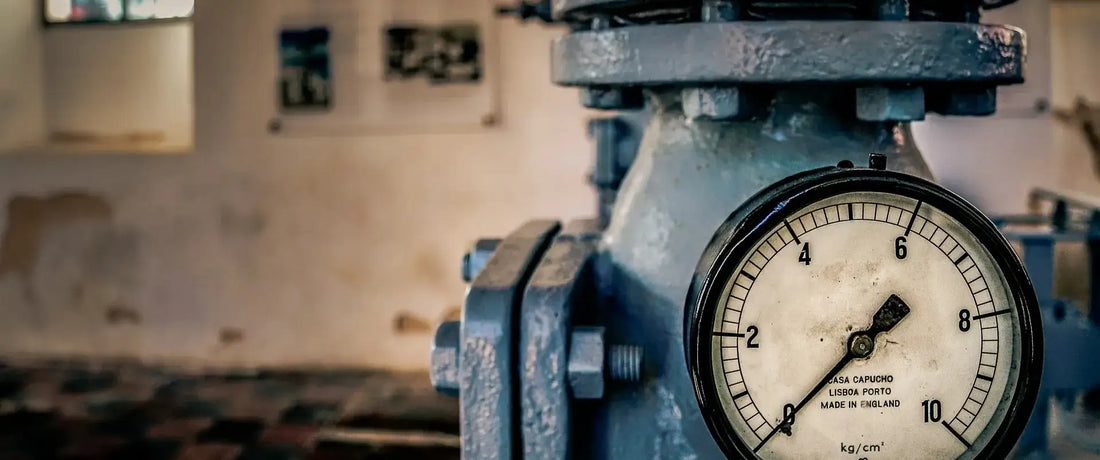

According to the form of the elastic sensitive element, the elastic element pressure gauge can generally be divided into bourdon tube type, diaphragm type, diaphragm type and bellows type. In various production fields, bourdon tube pressure gauges are the most common and most widely used pressure testing instruments. The bourdon tube pressure gauge is composed of measuring units (including joints, elastic elements, transmission mechanisms, etc.), indicators (including pointers and dials) and shell components (including watchcases, watch covers and watch glass).

Common problems in the measurement of bourdon tube pressure gauges

There are usually the following problems in the measurement of bourdon tube pressure gauges, which make the pressure gauge unable to meet the expected use requirements.

Leakage of pressure medium

When measuring the pressure of the bourdon tube, it is found that the phenomenon of air leakage and liquid leakage is relatively common. The main reason for the leakage of pressure transmission medium in the measurement of the pressure gauge is that the pressure gauge may have different degrees of wear at the joint during long-term use. It will lead to the leakage of the pressure transmission medium; the use of the bourdon tube pressure gauge is not standardized, such as the blockage of the bourdon tube, the leakage of the pressure transmission medium will also occur during the measurement; in the daily measurement, the use frequency of the booster equipment is high, The operating conditions of the pressure gauge are often poor. During the measurement process, the pressure increase port of the pressure gauge and the pressure source is prone to blockage, resulting in the leakage of the pressure transmission medium.

Indication out of tolerance

In the pressure gauge measurement, there are various reasons that may cause the pressure value to be out of tolerance. If the pointer is loose and the reading cannot be accurately read and the indication value is out of tolerance, this is the basic action to check the out-of-tolerance when measuring the pressure gauge; in the indication of out-of-tolerance, no matter how the measured data changes, the difference between the detected value and the actual standard value is always It is a fixed value, which is the most common form of out-of-tolerance, which may be caused by incorrect installation of the pointer; during measurement, if the proportional change in the indication error causes out-of-tolerance, it may be attributed to the difference in transmission ratio; if the measurement When the bourdon tube pressure gauge is out of tolerance only at a certain scale, it may be caused by the deformation of the bourdon tube caused by the long-term use of the bourdon tube.

The pointer of the meter cannot be fully deflected

The pointer of the pressure gauge indicator cannot be fully deflected during measurement, and the pointer does not seem to return to the zero-scale indication, or the pointer cannot reach the upper limit of the measurement, regardless of whether the pointer is in working condition. The reasons for the above problems are as follows: the transmission rate is too small for the pointer to reach a fully deflected state; the fixed position of the movement is wrong, so that the angle between the drive rod and the gear is too small to fully deflect; the active link and the passive connection object The connecting rod is too short, which affects the pressure angle of the transmission, so the pointer cannot reach the two extreme positions; the long-term use of the bourdon tube causes the initial displacement to change.

The pointer deflection of the bourdon tube pressure gauge is not stable

The phenomenon of beating and needle sticking occurs when the pressure gauge is measured. The most common cause is the bending or deformation of the pressure gauge pointer; or the pressure gauge may have foreign objects or wear on the connecting rods or gears of the movement components during long-term operation. , causing the shaft to be unable to drive smoothly when it rotates, which is not conducive to the interaction between the movement components, and the collision may cause the stitch to jump or even the needle to be stuck.

Measurement points of bourdon tube pressure gauge

Selection of pressure standard gauge

When measuring a pressure gauge, first select a suitable standard device. According to the regulations, the absolute value of the maximum allowable error of the standard device should not be greater than 1/4 of the absolute value of the maximum allowable error of the pressure gauge to be tested. For example: use a digital pressure gauge with a measuring range of (0~10) MPa and an accuracy class of 0.05 as the standard, and the measuring range of (0~6) MPa, whether the general pressure gauge with an accuracy class of 1.6 meets the requirements, It is necessary to see whether the following inequality is established: 10MPa×0.05%≤1/4×6MPa×1.6%, if this inequality is established, the requirements for the standard device are met. In addition, the measurement range of the test meter should be no larger than 3/4 of the measurement range of the standard meter as much as possible to better ensure the life and stability of the standard meter.

Correction of height difference of pressure surface

Due to the different sizes of the dials of the pressure gauges, there will be a pressure difference caused by the liquid level height difference between the pressure surface of the standard and the pressure gauge. Under normal circumstances, due to the small density of the gas, the error introduced by this difference in the measurement with gas (such as air, nitrogen, etc.) as the medium is small, and it is usually negligible. However, in the case where liquid (such as deionized water, transformer oil, etc.) is the pressure transmission medium, especially for the pressure gauge with a small upper limit of measurement, the error caused by this difference is more obvious. Therefore, when the pressure gauge is measured, if the height difference between the standard gauge and the pressure surface of the tested gauge is large, it can be properly corrected by the adapter to improve the accuracy and reliability of the measurement result.

The response to the out-of-tolerance indication

The indication error is an important measurement characteristic of the pressure gauge. The problems, causes and countermeasures in the indication measurement are as follows:

(1) The fixed increase or decrease of the pressure indication error is usually caused by the incorrect installation of the pointer of the pressure gauge. Needle repositioning.

(2) The verification error increases or decreases proportionally, mainly due to the inappropriate transmission ratio of the sector gear, which can be removed by adjusting the marking screw, so that the transmission ratio can be increased or decreased accordingly.

(3) If the rotation angle of the indicator is larger or smaller than the scale angle of the indexing plate, resulting in different speeds of the measured values, the adjustment method is to change the initial angle, that is, the angle between the connecting rod and the sector teeth.

(4) Some verification points are out of tolerance range. If the out of tolerance is caused by unstable deflection, the ratio should be stopped to check the fit between the parts. In addition, it may be caused by the deformation of the bourdon tube.

Withstand voltage test

When measuring the pressure gauge, proceed downward and upward with 0 MPa as the limit. At the upper limit of pressure (the upper limit of the vacuum pressure gauge is more than 90% of the local atmospheric pressure), the pressure source (or vacuum source) should be turned off, and the pressure should be stabilized at the upper limit of the pressure for 3 minutes to perform a withstand pressure test. The reason why the pressure test needs to reach the upper limit of measurement is that the accuracy of the elastic element pressure gauge mainly depends on the elastic hysteresis generated by the elastic sensitive element after the upper pressure withstand pressure returns to zero. These main characteristics are only reflected under the upper working pressure. Since the performance of the elastic element of the pressure gauge can be more comprehensively reflected, a pressure test is required when the pressure gauge is measured.

Measurement of vacuum part of pressure vacuum gauge

In the measurement of pressure vacuum gauges, it is often easy to ignore the requirements of different measurement upper limits for the measurement points of the vacuum part. During measurement, if the upper limit of the pressure measurement is (0.3~2.4)MPa, under the condition of pressure evacuated, the pointer of the pressure gauge should be able to point to the vacuum direction; if the upper limit of the pressure measurement is 0.15MPa, when the pressure gauge is measured, the vacuum part Two pressure points need to be measured; if the measurement line of the pressure gauge is 0.06 MPa, it is necessary to measure the indication error of three points on the vacuum part of the pressure vacuum gauge.

Conclusion

Bourdon tube pressure gauges are widely used in industrial and agricultural production, medical and health and other fields. The safety of pressure gauges is an important guarantee for people's lives and safe production. In the measurement of pressure gauges, it is necessary to continuously summarize work experience, continuously improve professional knowledge and business level, and escort pressure measurement.