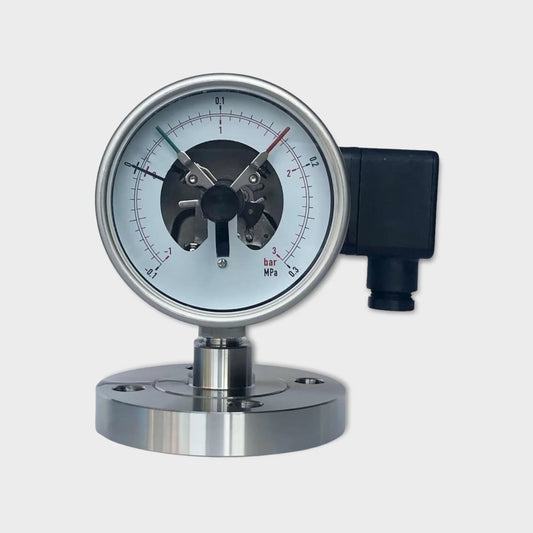

A pressure gauge with a diaphragm seal, also known as a diaphragm pressure gauge or gauge with remote diaphragm seal, is a specialized pressure measuring instrument that incorporates a flexible diaphragm to separate the process fluid from the pressure measuring element. This design is used when the process fluid is corrosive, viscous, contains particles, or is at a high temperature, and could potentially damage or affect the accuracy of the pressure gauge.

Here's an in-depth explanation of pressure gauges with diaphragm seals:

1. Purpose of Diaphragm Seal:

The primary purpose of a diaphragm seal is to protect the pressure measuring element of the gauge from the process fluid while still allowing accurate pressure measurements to be taken. The diaphragm acts as a barrier that isolates the gauge internals from the potentially harsh or challenging conditions of the process fluid.

2. Components and Operation:

A pressure gauge with a diaphragm seal comprises the following components:

- Diaphragm: The diaphragm is a flexible, elastic, and corrosion-resistant membrane placed between the process fluid and the gauge's pressure sensing element. It isolates the gauge internals from the fluid.

- Connection Fittings: The diaphragm seal assembly includes fittings to connect the diaphragm to the pressure source (process fluid).

- Fluid Fill Port: Some diaphragm seals have a fluid fill port to fill the space between the diaphragm and the pressure sensor with a suitable fill fluid, typically a silicone oil or other compatible fluid.

- Pressure Sensing Element: This can be a Bourdon tube, a pressure transducer, or any other mechanism used in a standard pressure gauge.

3. Working Principle:

When pressure is applied to the process fluid, the diaphragm transfers this pressure to the fill fluid between the diaphragm and the pressure sensing element. The fill fluid then transmits the pressure to the pressure sensing element. As a result, the pressure gauge indicates the pressure of the process fluid without the process fluid directly contacting the gauge's internal components.

4. Applications:

Pressure gauges with diaphragm seals are used in applications where the process fluid could be corrosive, abrasive, viscous, or at a high temperature. Some common applications include:

- Chemical Processing: Measuring pressures in corrosive chemical environments.

- Pharmaceutical and Food Industries: Measuring pressures in processes involving sensitive or hygienic materials.

- Pulp and Paper Manufacturing: Measuring pressures in pulp and paper production where the fluid may contain particles.

- Oil and Gas: Monitoring pressures in oil and gas refining processes.

- High-Temperature Processes: Measuring pressures in processes where extreme temperatures are involved.

5. Considerations:

When using pressure gauges with diaphragm seals:

- Diaphragm Material: Choose a diaphragm material that is compatible with the process fluid.

- Fill Fluid: Select a fill fluid that is compatible with the diaphragm material and the process fluid.

- Temperature and Pressure Ratings: Ensure that the diaphragm seal is rated for the temperature and pressure conditions of the process.

- Accuracy and Calibration: Regular calibration is important to maintain accurate measurements.

In summary, pressure gauges with diaphragm seals are designed to protect pressure sensing elements from harsh or challenging process fluids while still providing accurate pressure measurements. They are essential for applications where maintaining the integrity of the gauge internals is critical.