-

Tube Manometer Glycerin Filled Brass Connection

Regular price $3.28 USDRegular priceUnit price per -

Pressure Gauge 5 bar Back Mount Glycerine Filled Bayonet Ring

Regular price $7.58 USDRegular priceUnit price per -

Vacuum and Pressure Gauge with White Dial and black Needle

Regular price $6.95 USDRegular priceUnit price per -

Vacuum Manometer Gauge -1 Bar with Glycerin Filled

Regular price $3.16 USDRegular priceUnit price per -

0 to 15 Psi Pressure Gauge Filled with Glycerine 40mm Dial Red Needle

Regular price $3.59 USDRegular priceUnit price per -

Pressure Gauge For Water Three Scales Dial Manometer Analog

Regular price $1.59 USDRegular priceUnit price per -

50mm Glycerin Pressure Gauge 250 Psi for Gas Line

Regular price $4.85 USDRegular priceUnit price per -

Steam Pressure Gauge Stainless Steel Bourdon Tube

Regular price $7.58 USDRegular priceUnit price per -

Stainless Steel Gas Pressure Gauge Glycerine Filled Lower Mount

Regular price $14.55 USDRegular priceUnit price per -

EN837-1 Pressure Gauge Psi And Bar Dual Scale Glycerin Manometer

Regular price $3.79 USDRegular priceUnit price per -

50mm 400kpa 75psi Pressure Gauge For Air Compressor

Regular price $2.49 USDRegular priceUnit price per -

Pressure Gauge 300 Bar Made by SS316 with Glycerin Filled

Regular price $3.79 USDRegular priceUnit price per -

Vacuum Manometer U Tube Type Red Dial with Silicone Oil Filled

Regular price $3.79 USDRegular priceUnit price per -

Pressure Gauge 6000 PSI for Heavy Hydraulic Application

Regular price $4.68 USDRegular priceUnit price per -

400 Bar Pressure Gauge Liquid Filled Center Back Entry

Regular price $7.58 USDRegular priceUnit price per -

Hydraulic Oil Pressure Gauge Back Entry Needle Manometer 316SS

Regular price $6.32 USDRegular priceUnit price per -

3000 Psi Hydraulic Pressure Gauge Dual Scale Oil Filled Case

Regular price $7.58 USDRegular priceUnit price per -

Gas Manometer Gauge SUS Material Bayonet Ring

Regular price $7.58 USDRegular priceUnit price per -

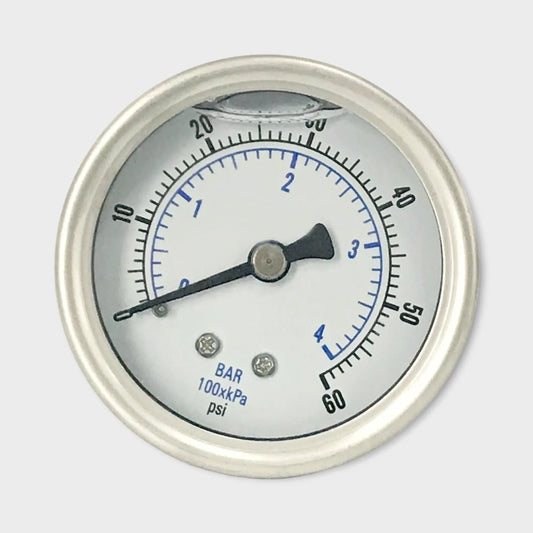

Water Pressure Gauge with Liquid Filled 60 Psi 4bar

Regular price $7.58 USDRegular priceUnit price per -

0 to 300 Psi Pressure Gauge 2.5 Inch Panel Mount Stainless Steel Manometer

Regular price $6.28 USDRegular priceUnit price per

Understanding the Benefits of an Oil Filled Pressure Gauge

In industries where accurate pressure measurement is vital for operational efficiency and safety, the choice of pressure gauge plays a crucial role. Among the various types of pressure gauges available in the market, the oil filled pressure gauge has emerged as a preferred choice for many applications due to its numerous benefits. In this article, we'll delve into the advantages of using an oil filled pressure gauge, including its variants like glycerin pressure gauges, pressure gauges filled with glycerin, liquid filled pressure gauges, and glycerin type pressure gauges.

What is an Oil Filled Pressure Gauge?

An oil filled pressure gauge is a specialized type of pressure gauge that is filled with a damping fluid, typically oil, glycerin, or silicone, to enhance its performance and accuracy. The damping fluid helps to stabilize the needle, reducing the effects of vibration and pulsation, and providing more consistent and accurate pressure readings over time.

Key Benefits of an Oil Filled Pressure Gauge

1. Enhanced Durability and Longevity

- Protection Against Vibrations: The damping fluid absorbs vibrations, reducing wear and tear on internal components.

- Extended Lifespan: The protection provided by the oil filling extends the gauge's lifespan, resulting in reduced maintenance costs.

2. Improved Accuracy and Stability

- Stabilized Readings: The damping effect of the oil ensures stabilized readings by minimizing needle fluctuations caused by pulsation or vibration.

- Consistent Performance: The enhanced stability leads to consistent and accurate pressure readings over time.

3. Resistance to Environmental Factors

- Protection Against Corrosion: The oil filling provides an additional layer of protection against corrosion and environmental factors.

- Temperature Stability: Oil filled pressure gauges often exhibit better temperature stability compared to dry gauges, making them suitable for a wider range of applications.

Variants of Oil Filled Pressure Gauges

Glycerin Pressure Gauge

A glycerin pressure gauge is a specific type of oil filled pressure gauge that uses glycerin as the damping fluid. Glycerin offers excellent viscosity and temperature stability, making it a popular choice for applications requiring high accuracy and reliability.

Pressure Gauge Filled with Glycerin

This refers to a pressure gauge that is specifically filled with glycerin as the damping fluid. These gauges offer the benefits of glycerin, including excellent viscosity and temperature stability, and are ideal for applications where high accuracy is required.

Liquid Filled Pressure Gauge

A liquid filled pressure gauge is a more general term that refers to any pressure gauge filled with a liquid damping fluid, which can be oil, glycerin, or silicone. While oil and glycerin are the most common damping fluids used, silicone is also used in certain applications where compatibility with specific materials is required.

Glycerin Type Pressure Gauge

A glycerin type pressure gauge refers to a pressure gauge that is designed to be compatible with glycerin filling. While it may not be filled with glycerin by default, it is designed to accommodate glycerin filling if required. This type of pressure gauge offers flexibility and can be filled with glycerin or other damping fluids based on the application's requirements.

Conclusion

Oil filled pressure gauges offer numerous advantages over traditional dry gauges, making them a preferred choice for many industrial and commercial applications. Whether you opt for a glycerin pressure gauge, a pressure gauge filled with glycerin, a liquid filled pressure gauge, or a glycerin type pressure gauge, these gauges provide reliable and consistent performance in demanding conditions.

At WESEN Technologies, we offer a wide range of oil filled pressure gauges and their variants to meet your specific requirements. Our gauges are designed and manufactured to the highest standards to ensure accuracy, reliability, and durability in all types of applications.

Contact us today to learn more about our oil filled pressure gauge solutions and how we can help you select the right gauge for your needs. We look forward to assisting you with all your pressure measurement needs!