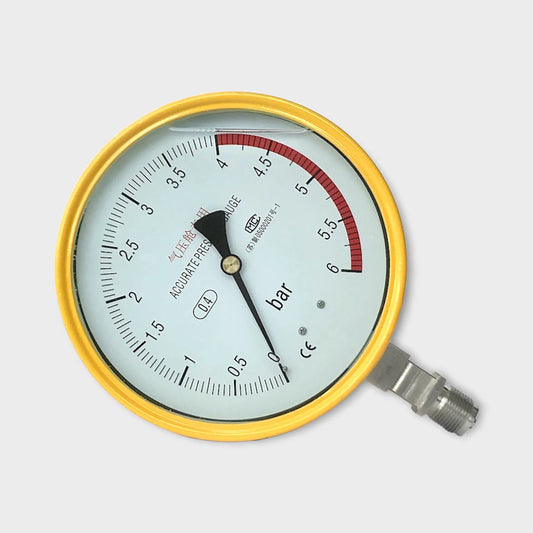

A Precision Pressure Gauge is a highly accurate and specialized instrument designed for the precise measurement and monitoring of pressure in various industrial, laboratory, and scientific applications. These gauges are engineered to provide exceptionally accurate and reliable pressure readings, often with a minimal margin of error. Here are some key characteristics and features of Precision Pressure Gauges:

1. Exceptional Accuracy: Precision pressure gauges are known for their superior accuracy. They are calibrated to provide measurements that are very close to the true pressure within the system they are monitoring. This level of accuracy is crucial in applications where precise pressure control is required.

2. High Resolution: These gauges typically offer high resolution, allowing them to detect even the slightest changes in pressure. This makes them well-suited for applications that demand fine adjustments or require close monitoring of pressure fluctuations.

3. Precise Mechanical Movements: Precision pressure gauges use precise mechanical movements, such as Bourdon tubes, diaphragms, or bellows, to convert pressure into accurate readings. The internal mechanisms are carefully designed and manufactured to minimize measurement errors.

4. Calibration: Precision gauges undergo rigorous calibration processes to ensure their accuracy. Calibration may be traceable to national standards, and the gauges are periodically recalibrated to maintain their precision over time.

5. Wide Pressure Range: Depending on the specific application, precision pressure gauges can cover a broad range of pressures, from very low vacuum pressures to extremely high pressures. They are available in various pressure ranges to suit different needs.

6. Robust Construction: These gauges are often built with durable materials and strong casings to withstand harsh environments and ensure long-term accuracy. They are designed to be reliable and long-lasting.

7. Liquid-Filled or Dampened Gauges: Some precision pressure gauges are filled with a liquid (typically glycerin) or equipped with dampening mechanisms to reduce needle vibration and provide stable readings, especially in dynamic or fluctuating pressure conditions.

8. Certifications: Precision pressure gauges may come with certifications to comply with industry or safety standards. For example, they might meet ISO, ANSI, or other relevant standards.

9. Versatility: Precision Pressure Gauges find applications in a wide range of industries, including aerospace, manufacturing, pharmaceuticals, petrochemicals, research and development, and quality control. They are used wherever precise pressure measurement is vital.

10. Calibration and Maintenance: To maintain their accuracy, precision pressure gauges are often regularly calibrated and maintained to ensure they continue to provide dependable and accurate readings over time.

Precision Pressure Gauges play a critical role in industries and applications where even slight variations in pressure can lead to significant consequences. Whether in laboratories, quality control processes, research and development, or any scenario requiring highly accurate pressure measurements, these gauges are indispensable tools for ensuring precise pressure control and safety.