Electric Contact Pressure Gauges: Precision Meets Connectivity

In today's fast-paced world, industries demand more than just accurate pressure measurement. They require real-time data, connectivity, and the ability to respond swiftly to changes in their processes. This is where Contact Pressure Gauges step in, offering the perfect blend of precision and connectivity. In this article, we'll explore the world of these advanced instruments, highlighting their features, advantages, and the pivotal role they play in ensuring efficiency and reliability in critical applications.

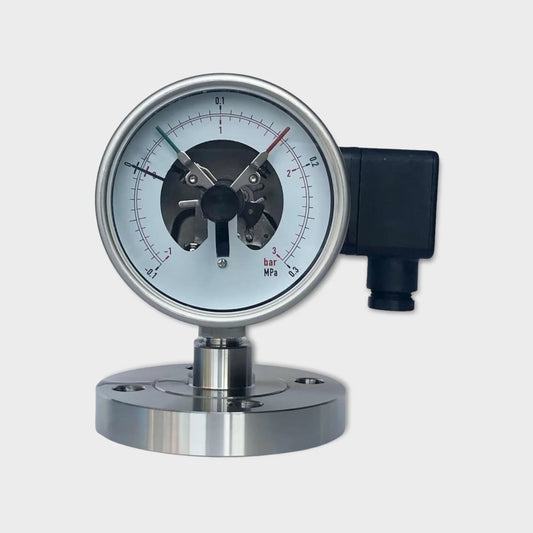

Unveiling Electric Contact Pressure Gauges

Pressure Gauges with switch contacts are sophisticated devices designed for applications where not only precise pressure measurement is required, but also the need for instant data feedback and remote monitoring. These gauges are equipped with switch contacts that can send signals or trigger alarms based on pressure thresholds, making them an indispensable tool for process control.

Key Components of Electric Contact Pressure Gauges

These gauges are equipped with several core components, each playing a vital role in their operation:

1. Pressure Sensor: This sensor, often a Bourdon tube or diaphragm, reacts to changes in pressure. It translates these changes into electrical signals.

2. Dial Face: Just like traditional pressure gauges, Contact Pressure Gauges have a dial face to display pressure readings.

3. Electrical Contacts: These contacts are the unique feature of these gauges. They can be set to activate at specific pressure levels, serving as triggers for alarms, switches, or control systems.

4. Pressure Units: Contact Pressure Gauges can be calibrated to display pressure in various units to suit different applications.

The Advantages of Electric Contact Pressure Gauges

1. Real-Time Monitoring: These gauges provide real-time data, allowing operators to monitor and control processes remotely.

2. Alarm and Control: The electrical contacts in these manometers can be configured to activate alarms or control systems when pressure reaches critical levels, ensuring timely intervention.

3. Precision: Pressure gauges with switch contacts maintain the same precision as traditional pressure gauges, ensuring that the readings are accurate and reliable.

4. Connectivity: These gauges can be integrated into process control systems and can communicate data to central control rooms or remote devices.

Applications of Electric Contact Pressure Gauges

Contact Pressure Gauges find their use in numerous industries and applications, including but not limited to:

- Oil and Gas: Monitoring pressure in pipelines and drilling operations.

- Manufacturing: Controlling pressure in industrial processes.

- Aerospace: Ensuring safety in aircraft systems.

- Water Treatment: Managing pressure in water distribution and treatment plants.

Selecting the Right Electric Contact Pressure Gauge

Choosing the right Electric Contact Pressure Gauge is vital to match the specific needs of your application. Factors such as the pressure range, type of electrical contacts, and compatibility with control systems should all be considered. At WESEN Technologies, we offer a range of Contact Pressure Gauges designed to meet various requirements. Our team of experts is here to assist you in making the right choice.

In conclusion, Electric Contact Pressure Gauges are the intelligent solution for those who demand not only precision but also real-time control and connectivity. If you have any questions or need guidance in selecting the perfect Contact Pressure Gauge for your requirements, please don't hesitate to contact us at sales@wesen-tech.com.

WESEN Technologies - Your Trusted Partner for Advanced Electric Contact Pressure Gauges.